IKEA figured something out that most furniture companies missed for decades: design for shipping is design for assembly.

When Ingvar Kamprad started flat-packing furniture in 1956, it wasn't primarily about making assembly easier for customers. It was about fitting more products into trucks. Shipping air is expensive; shipping flat panels is cheap.

But the same constraint that optimized shipping — everything must disassemble into flat pieces — also created products that customers could assemble themselves. The constraint became a feature.

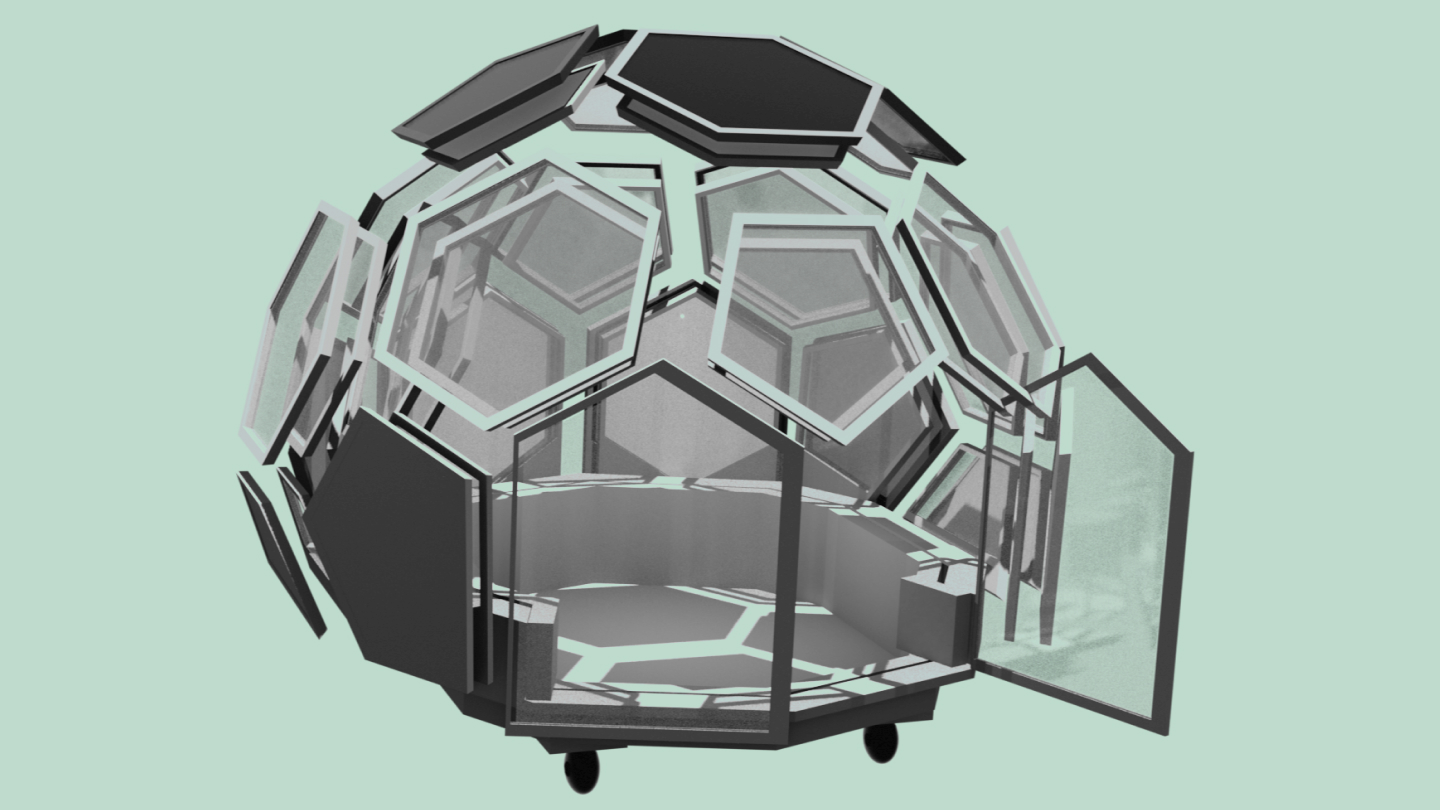

This insight is core to how we design the Thiosphere.

The Problem with Prefabricated Structures

The traditional approach to selling structures: build them in a factory, ship them complete.

This creates problems:

Shipping cost: A 12-foot-diameter dome is roughly 12 feet in every dimension. It ships as oversized freight, requiring special trucks, special permits, and special handling. Shipping cost can be 30-50% of the product price.

Delivery access: Can a semi truck reach your backyard? Most can't. Now you need a crane to lift the structure over your house, or disassembly at the delivery point (negating the prefab advantage).

Damage risk: Complete structures are harder to protect in transit. One hard bump and you have cracked panels, misaligned joints, warranty claims.

Limited customization: Once it's built, it's built. Want a different door position? Want extra windows? Too late.

Companies that sell prefab structures charge premium prices partly because shipping and handling are genuinely expensive.

The Flat-Pack Alternative

The Thiosphere takes a different approach: design every component to be flat.

Every panel is cut from 4x8-foot plywood or OSB sheets. Every framing member is straight lumber (2x4s, 2x6s). Every piece of the structure lies flat.

This means:

Standard shipping: Everything fits on a pallet or in a utility trailer. No oversized freight, no special handling. You could fit a complete Thiosphere kit in the back of a pickup truck.

Any access point: If you can walk to your backyard, you can carry Thiosphere components to your backyard. No crane required. No driving a semi through your neighbor's yard.

Damage resistance: Flat panels are easier to protect and less vulnerable to shipping damage. A panel can flex; a complete structure can't.

Full customization: Since you're building it anyway, modifications are easy. Want a different door position? Cut the door opening where you want it. Want extra windows? Add them. The design is a starting point, not a finished product.

Design Constraints That Enable Building

Here's the deeper insight: the constraints that enable flat-pack shipping also enable DIY building.

Standard materials: If components must fit in standard shipping, they must be cut from standard materials. Standard materials mean anyone can source them locally. You don't need specialty suppliers; you need Home Depot.

Straight cuts: If components must lie flat, they need to be made with straight cuts. Straight cuts mean table saws and circular saws — tools most DIYers own or can access. No CNC router required.

Reasonable weight: If components must be carried by delivery drivers, they must have reasonable weight. Reasonable weight means one or two people can maneuver them during assembly.

Clear assembly sequence: If components ship flat and assemble on-site, there must be a clear assembly sequence. This sequence becomes the build instructions.

Every constraint we accepted for shipping made the structure easier to build. The constraint wasn't a sacrifice; it was a design tool.

The Cut List as Contract

When you get the Thiosphere handbook, you get a complete cut list. Every piece of lumber and panel, with exact dimensions.

| Component | Material | Quantity | Dimensions |

|-----------|----------|----------|------------|

| Floor panel A | 3/4" plywood | 6 | 48" x 48" |

| Floor panel B | 3/4" plywood | 6 | 48" x 24" |

| Wall frame vertical | 2x4 | 24 | 92.5" |

| Wall frame horizontal | 2x4 | 48 | 45" |

| ... | ... | ... | ... |

This list serves multiple purposes:

Material purchasing: Take the list to any lumber yard. Get exactly what you need, nothing extra.

Cutting preparation: Set up your saw, make all cuts of one dimension, move to the next. Efficient workflow.

Quality control: If a piece doesn't match the list, something's wrong. Measure twice, cut once.

Assembly reference: During build, the list becomes your checklist. Each component has a name; each name appears in the instructions.

The cut list is the contract between design and reality. If you execute the list correctly, the structure works. No interpretation required.

Assembly Sequence as Story

Traditional construction plans show the finished product — a building drawing with all components in place. Useful for permits; useless for building.

The Thiosphere handbook uses assembly sequence diagrams. Each step shows:

- What you're adding

- What it connects to

- What fasteners to use

- What to check before proceeding

It's a story: First this, then this, then this. Each step builds on the previous. Each step is achievable by one or two people with basic tools.

The sequence matters. We've tested the order:

Platform first: Level, stable, protected from ground moisture. Everything else depends on this foundation.

Outer shell second: Weather protection goes up before insulation, so you have shelter during construction.

Insulation third: Protected from weather by the outer shell, installed before interior finish.

Inner shell fourth: Clean interior surfaces, installed once insulation is secure.

Finishes last: Benches, shelving, trim — the customizable parts that make the space yours.

If you try to do interior work before the outer shell is complete, you're racing weather. If you try to insulate before the structure is closed in, moisture becomes a problem. The sequence exists for reasons.

Lessons from IKEA's Mistakes

IKEA gets a lot right, but they've made mistakes we learn from:

Over-reliance on proprietary hardware: IKEA furniture uses proprietary cam locks, dowels, and fittings. Lose a piece and you're stuck waiting for replacement parts.

The Thiosphere uses standard fasteners: deck screws, carriage bolts, construction adhesive. Everything available at any hardware store. If you strip a screw, walk to the store for more.

Unclear diagrams: IKEA's wordless instructions are famously ambiguous. Which piece is this? Is that arrow pointing to the hole or the screw?

Our handbook uses photographs, dimensions, and text explanations alongside diagrams. If something isn't clear from the diagram, the text clarifies. If the text isn't clear, the photograph shows what it should look like.

Tolerance for misalignment: IKEA furniture is designed to be "good enough" — the tolerances accommodate imprecise assembly. That's fine for a bookshelf; it's not acceptable for a structure that needs to be weather-tight.

The Thiosphere specifies tolerances. "Panel edges should align within 1/8 inch." "Check platform level before proceeding — maximum deviation 1/4 inch over 8 feet." If you're outside tolerance, stop and fix it.

What Flat-Pack Doesn't Do

I want to be honest about limitations:

Flat-pack doesn't eliminate skill: You still need to cut accurately, measure correctly, and use tools safely. The design reduces complexity; it doesn't eliminate it.

Flat-pack doesn't eliminate time: Even with efficient design, building takes 40-60 hours. You're doing the assembly that a factory would do. That's the tradeoff for lower cost.

Flat-pack doesn't eliminate weight: A 4x8 sheet of 3/4" plywood weighs about 60 pounds. You'll be moving 30+ of them. Plan for the physical work.

Flat-pack doesn't eliminate learning curve: Your first build will be slower than your tenth. That's fine — you're building skill along with structure.

The promise of flat-pack is accessibility and customization, not effortlessness. If you want effortless, hire a contractor to build something conventional. You'll pay more, get less customization, but save your weekends.

The Future of Flat-Pack Building

I believe flat-pack structures will become increasingly common. Here's why:

Housing costs keep rising: As traditional construction becomes less affordable, DIY approaches become more attractive. Flat-pack lowers the entry barrier.

Tools keep improving: Cordless tools, laser levels, portable workbenches — the equipment for DIY building is better and cheaper than ever.

Information keeps spreading: YouTube, online communities, detailed handbooks — the knowledge gap that kept people from building is closing.

Land use keeps changing: ADU regulations, flexible zoning, remote work — more people have reasons to add space to their properties.

The Thiosphere is one approach. Others will emerge. The principle — design for shipping becomes design for building — will spread.

Try It Yourself

The simplest way to understand flat-pack building is to build something.

The Thiosphere handbook starts with a small project: a tool storage box using the same construction principles as the full structure. Same flat panels, same assembly sequence approach, same fastening methods.

Build the box first. Make your mistakes on something small. Learn how the materials behave. Then scale up to the structure.

Design in 2D. Build in 3D. Ship flat, assemble anywhere.

Get the Thiosphere Handbook — complete cut lists, assembly sequences, and design documentation.

Try the configurator — see how the flat components create 3D structures.

Join our community — builders helping builders solve problems.