At first glance, the Thiosphere looks like a geodesic dome. People see the spherical shape, the triangular panels, and assume we're building another Buckminster Fuller tribute.

We're not.

The Thiosphere is fundamentally different from a geodesic dome — in ways that make it dramatically easier to build, more weather-resistant, and more practical for DIY construction. This post explains those differences, because if you're considering building one, you need to understand what you're actually getting.

The Geodesic Dome: Brilliant But Frustrating

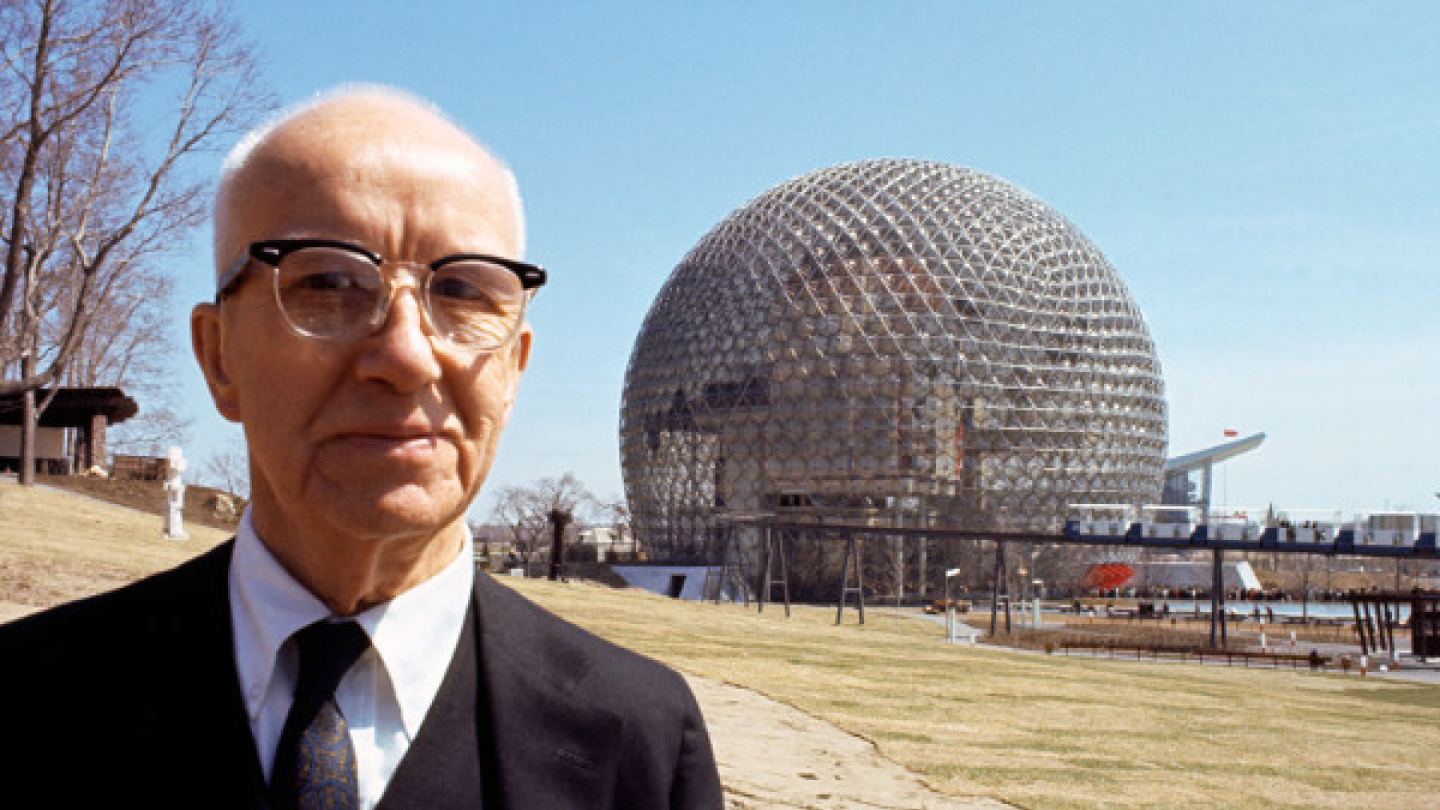

Let's start by giving Bucky his due. The geodesic dome, patented by R. Buckminster Fuller in 1954, is a genuine engineering marvel.

The core insight: A sphere encloses the maximum volume with the minimum surface area. If you want to heat or cool a space efficiently, a sphere is mathematically optimal. Less surface area = less heat loss.

The geodesic approach: Approximate a sphere using a network of triangles. The triangular structure distributes stress evenly, making geodesic domes incredibly strong for their weight.

Geodesic domes have housed radar stations in Antarctica, covered sports stadiums, and served as iconic architecture (think Epcot's Spaceship Earth). For large-scale construction with professional builders, they're fantastic.

For backyard DIY projects? They're a nightmare.

The Three Problems with Geodesic Domes

After studying dozens of DIY geodesic dome builds, three problems appear over and over:

Problem 1: Joint Complexity

A classic geodesic dome has 5-way and 6-way joints — places where five or six struts come together at different angles. Each joint requires custom hardware. Each angle must be precise.

DIY builders on forums report spending 40% of their total build time on joint fabrication alone. One builder I talked to spent three weekends just building jigs to cut the right angles.

And if you get a joint wrong? The error propagates. A dome that's off by 2° at one joint can be off by 12° three joints later.

Problem 2: Waterproofing Nightmares

Here's the dirty secret of geodesic domes: they leak.

Not all of them. Professionally-built domes with commercial-grade sealing systems can be watertight. But DIY domes? Look at any dome builder forum and you'll find endless threads about water intrusion.

The problem is geometry. All those joints create seams. Water finds seams. A traditional rectangular roof sheds water in one direction — down. A dome sends water in every direction, across dozens of joints.

Some builders spend more on waterproofing membrane than on structural materials. And they still get leaks.

Problem 3: Insulation Challenges

The curved interior of a dome makes standard insulation awkward. Fiberglass batts want to lie flat. Spray foam works but requires professional installation. Every odd angle creates a potential thermal bridge.

Plus, there's the condensation problem. Warm air rises to the top of the dome, hits the cold shell, and condenses. Dome owners in humid climates report constant battles with dripping ceilings.

The Thiosphere Approach: Same Benefits, Different Architecture

The Thiosphere delivers the same benefits as a geodesic dome — efficient use of space, excellent thermal properties, striking appearance — while solving the practical problems.

Here's how:

Solution 1: Flat Panel Construction

Instead of a network of struts meeting at complex joints, the Thiosphere uses flat panels that connect at simple angles.

Each panel is cut from standard plywood or OSB. The cuts are straight lines — no compound angles, no custom jigs. A table saw or circular saw is all you need.

The panels connect using standard lumber (2x4s) at their edges. The joints are simple lap joints or butt joints, reinforced with screws. Anyone who's built a basic box can build these joints.

Build time for joints: Instead of 40% of the project, joints take about 10% of total time.

Solution 2: Nested Double-Shell Design

Here's the key innovation: the Thiosphere isn't one dome — it's two nested domes with an air gap between them.

The outer shell handles weather. The inner shell defines the living space. Between them: a continuous air gap that provides insulation and a drainage plane.

If water penetrates the outer shell (and some will, eventually, in any structure), it hits the air gap. The gap is designed to channel water down and out, never reaching the inner shell.

This is the same principle used in high-end boat hulls and aircraft fuselages. It's not new — it's just rarely applied to small structures because it requires more material. We decided the extra plywood was worth the peace of mind.

Solution 3: Elevated Platform Base

Geodesic domes typically sit on a foundation — concrete slab, wooden deck, or directly on ground.

The Thiosphere sits on an elevated platform, like a treehouse without the tree. The platform raises the structure 12-18" off the ground (adjustable based on terrain).

Benefits:

- Drainage: Water doesn't pool around the base

- Insulation: Air gap under the floor adds thermal protection

- Leveling: Uneven ground is irrelevant — you level the platform, not the ground

- Mobility: With removable connections, the entire structure can be relocated

- Ventilation: Air circulates under the floor, preventing moisture buildup

The Math: Thiosphere vs. Traditional Geodesic

Let me be concrete about what this means for a typical DIY builder:

| Aspect | 16' Geodesic Dome | 16' Thiosphere |

|--------|------------------|----------------|

| Unique cut angles | 15+ | 3 |

| Joint types | 5-way, 6-way | Simple lap joints |

| Specialized hardware | Hub connectors, custom brackets | Standard screws, bolts |

| Waterproofing approach | Membrane + sealant at every joint | Drainage plane built in |

| Build time (experienced) | 80-120 hours | 40-60 hours |

| Build time (first timer) | 150-200 hours | 60-80 hours |

| Material cost (lumber) | $1,800-2,400 | $2,000-2,600 |

Yes, the Thiosphere uses slightly more material. The double shell requires more plywood. But the time savings more than compensate, especially when you factor in the waterproofing labor you don't need.

What Bucky Would Actually Think

I titled this post "Bucky would approve," which is presumptuous since he died in 1983 and never saw a Thiosphere.

But if you read Fuller's writings, he wasn't attached to the geodesic geometry for its own sake. He was obsessed with doing more with less — achieving maximum function with minimum resources.

His 1969 book Operating Manual for Spaceship Earth argues that the purpose of design is to serve human needs efficiently. The geodesic dome was his answer for large-scale structures with 1950s materials and manufacturing.

The Thiosphere is an answer for small-scale structures with 2020s materials and DIY constraints. Different problem, different solution, same philosophy.

If someone showed Bucky a structure that used standard lumber, required no specialized skills, could be built in a weekend, and solved the leaking problem that plagued his domes — I think he'd nod and say "good job."

Then he'd probably tell you three ways to improve it. That was Bucky.

When to Actually Build a Geodesic Dome

I've spent this whole post explaining why the Thiosphere is better for DIY builders. But honesty requires acknowledging when geodesic domes make sense:

- Large scale: For structures over 30' diameter, geodesic geometry shines. The strength-to-weight ratio becomes increasingly favorable as size increases.

- Professional installation: If you're hiring builders who've done domes before, the joint complexity is less of an issue.

- Specific aesthetics: Some people want the classic Fuller look. No judgment — it's iconic for a reason.

- Permanent installation with serious waterproofing budget: If you can afford EPDM membrane properly installed, domes can be sealed.

For backyard structures under 20', built by DIYers, meant to be assembled in a weekend? The Thiosphere is the better choice.

See For Yourself

The best way to understand the difference is to look at the actual plans. The Thiosphere handbook includes:

- Exploded diagrams showing how panels fit together

- Cut lists for every piece of lumber

- Step-by-step assembly sequences

- Detail drawings of each joint type

- Comparison photos with geodesic construction

You can also explore the 3D model in our online configurator — no purchase required. Rotate it, zoom in on joints, see exactly what you'd be building.

Try the WTFosphere Configurator — Design your structure in 3D, free.

Get the Thiosphere Handbook — Complete plans for $29.

Questions about the design? Join our Discord and ask.